How to Buy Industrial Engine and Compressor Parts

How to Buy Industrial Engine and Compressor Parts

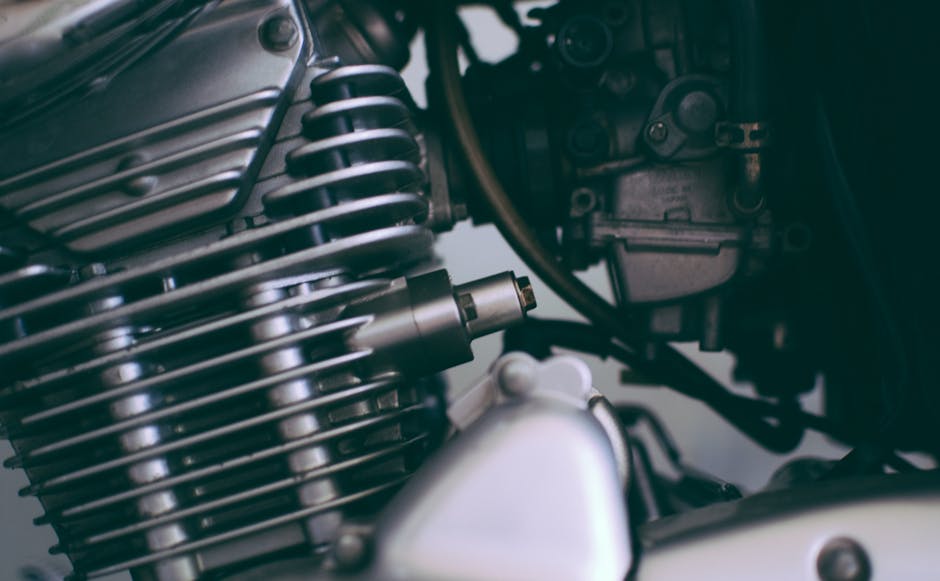

Purchasing industrial machine and equipment require one to be vigilant. A lot of things need to be put in mind when deciding on which industrial engine and compressor parts to buy. Most people do not realize the importance of acquiring the best machine ad equipment in the market until they find the one they have bought to be ineffective. An industrial engine is the heart of your production and manufacturing company. If your engine together with compressor parts are not functioning correctly, then there will be a definite delay in production which may, in turn, lead to loosing of clients. There are several ways discussed in this article on how you can buy an industrial engine and compressor parts, which will be best for your business.

To start with a look at the compatibility. Not every engine and compressor parts will be compatible with your machine. In most cases, the device requires engines and compressor parts made of the same brand. The size of your device should also matter. Different machine sizes need different engine sizes to propel them. If your machines are large, then you will require more stringer engines to generate more power to run them. With technology, however, size does not matter but the output. An individual should compare the energy produced by the engine to one required by the machine to run. The output and input of the engine should match to avoid instances where electric shock and short-circuiting occur due to a lot of power being generated for ignition of the engine and the machine.

Secondly, another factor to consider when buying an industrial engine and compressor parts is consumption. Different engines have varying consumption levels. Some engines will consume more, while others are less regardless of the amount of work they are doing. An individual should calculate the number of hours the engine will be running to the amount of fuel needed and find out whether they will afford. With the compressors, part one should evaluate how often they will have to bring in maintenance services. The total cost to be incurred should by the individual be affordable to them. If the cost to be incurred on fuel and maintenance is high than what an individual can afford, they should look for another alternative. It is important to look for an energy-saving engine, which in turn should be environmentally friendly.

Thirdly, one should evaluate the type of machines they have in the kind of engine and compressor parts they want to buy and understand their needs. Different machinery runs on different engine. The engine used for running a milling factory is completely different for one running a tannery factory. An individual can consult with an expert before deciding on which industrial engine and compressor parts to buy. Getting enough information and knowledge allows out to make the right choice when acquiring industrial engine and compressor parts. One should buy an industrial motor and compressor parts which suits their business best. Checking on the quality and brand is also of much importance.

Looking On The Bright Side of Machines

The 10 Most Unanswered Questions about Work